Please drink responsibly.

Please drink responsibly.

Distillation is a technique in gin-making that transforms individual ingredients into the harmoniously blended Gin de France that you enjoy straight up or mixed in a delicious cocktail.

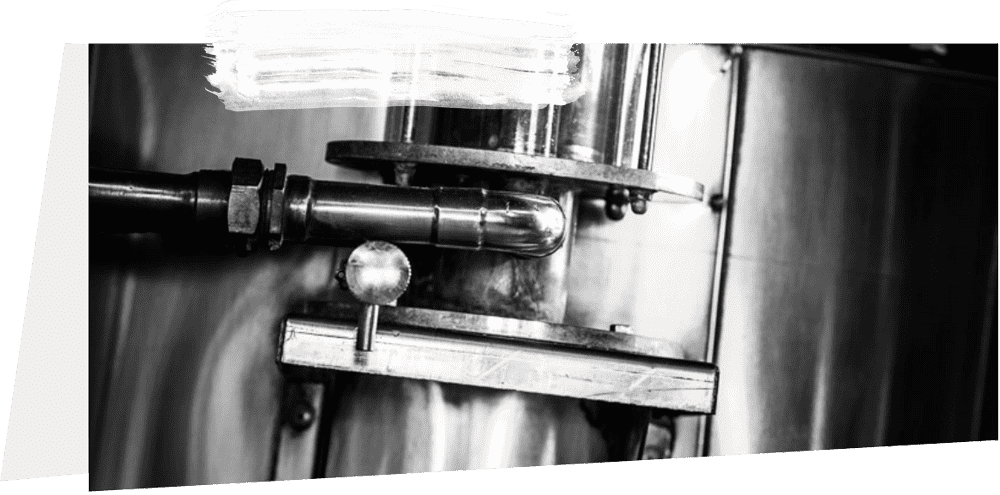

It is a process that’s been developed and perfected over 20 centuries that has as much impact on the resulting gin as the ingredients themselves. Master distillers rely on specific equipment such as Charente-inspired and Florentine alembics, each one playing an important role in creating the perfect infusions and distillates to flavor the gin.

Distillation is a chemical process used to extract the purest essence of each ingredient. When a liquid is heated its components separate and transform from liquid to gas. Once separated, the gas is then condensed back into a more pure liquid, otherwise known as the distillate.

This method first appeared in the 1st century B.C. among Greek alchemists. Alembics, the vessels used in distillation, were first described in the 4th century A.D. by Zosime de Panapolis. The 8th century saw a revolution in the art of distillation when Geber and other Arab alchemists improved upon the earliest iterations of alembics and other tools, many of which are still used today.

Italy was home to Europe’s first brandies, created in the 12th century. Alchemists of the time were inspired to write discourses on early Greek and Arabic alembic descriptions. Pretty soon these treatises spread over the continent and distillation apparatuses— from retorts to stills and lateral beakers— were modified to perfection.

The next revolution in the art of distillation was the advent of the pot still, made up of a copper still and cooling coils. Following this invention, the 16th century saw new spirits appearing all over Europe, including the Dutch spirit genever, which evolved into gin once making its way across the Channel. Distillation was further tweaked in the 19th and 20th centuries with evolutions in temperature control, precision equipment, and chemical component analysis. Through all these advances in technology, one thing has remained the same through the centuries: the human factor. Operating all of these apparatuses is a master distiller using their expertise and making the important choices that lead to a high quality spirit.

Gin distillation: the savoir-faire

The method of distilling gin is not too dissimilar from the process of distilling other spirits. It requires a base alcohol, aromatic plants, and an alembic. But to produce an exceptional gin of the highest standard, it is imperative to find the perfect balance and perfect amounts of every ingredient so that each of the aromatic plants and spices plays an integral role in the final product.

Inspired by the original gin makers of the Middle Ages, Jean-Sébastien Robicquet decided to use grape brandy as the base for G’Vine, despite the fact that 99% of today’s gin is made from fermented grains. The process of making distilled gin starts when the neutral base alcohol is placed in a vessel called an alembic. The accent plants and spices are either mixed in directly in the case of maceration, or suspended in the case of infusion. When brought to a boil the alcohol emits vapors that are impregnated with the plant and spice aromas, and then put in a cooling column where they are condensed back into liquid form. Distilled gin is the purest since it doesn’t make use of any artificial flavors, like in compound gin.

The remaining distillates rest in vats for a few hours before being diluted with water to reach the required degree of alcohol, which is at least 37.5% for gin. The choice of water plays an important role as it must not distort the carefully blended flavors of the gin. Afterwards, is the assemblage– if necessary– followed by a cold filtration at around 28.4°F, and finally bottling.

Each distillery possesses its own little secrets of manufacturing. Maison Villevert uses a small Florentine alembic most typically used in perfumery. This is how they capture the delicate vine blossom aromas.

Alembics can take a variety of forms in addition to the Florentine. Some of the most common forms are the pot still, the onion shape, and the boil ball, as well as the less common pear shape, bell shape, and Lomond Still. While all alembic styles differ slightly in shape, each one has a cooling column and a gooseneck to collect precious distillates. As well as variations in alembics, heating systems can vary too, however most modern distilleries use steam. All of the different techniques that go into alcohol distillation lead to production of different kinds of gin. For example: